Laboratory

sealed jaw crushers is on medium and fine

crushed materials for the purposes of laboratory and production and especially

as environmental protection equipment for the coal, electricity, Gold Mining Machine, geology, chemistry, metallurgy -, building materials and other

industries. The product is indicated by the only company of the former Ministry

of Geology and Mineral Resources, manufactured in accordance with industry

standards.

XPC model Sealed

Jaw Crusher is a new generation of crushing plants with slightly open dynamic

and static jaws, convenient cleaning and without mixing of samples. It is

capable of fine and medium refractive a variety of ores and materials having a

compressive strength of 24kg/cm2 and down. with large crushing ratio, uniform

particle size and setting the output size.

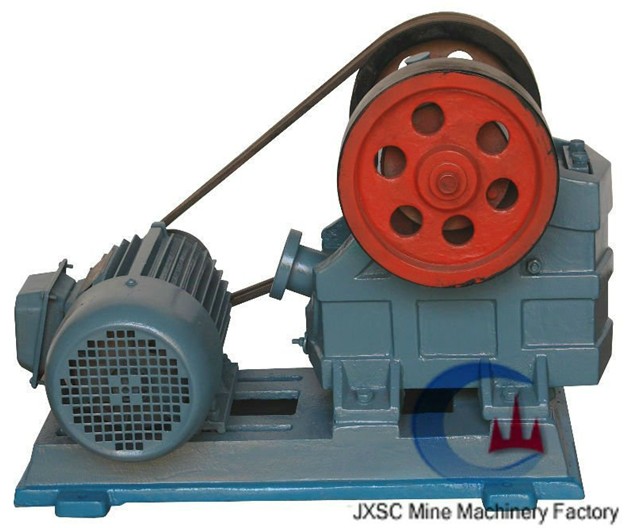

I. Main Design

and functional principle

This machine is

composed mainly of machine body, movable jaw, eccentric shaft, jaw plate,

flywheel, pulley, movable part, motor, hopper and the collecting funnel.

The three angles

of motor pulley drive the eccentric shaft through the pulley to get move the

movable jaw along the track already adapted to crush as the materials in the

crushing chamber.

The machine body

is all steel. Fixed jaw plate is mounted on its front wall. Edge plates are

provided on the side wall of the frame on the left and right of the crushing

chamber, in order to prevent the abrasion of the side wall of the frame, is

mounted.

The movable jaw

is a form of casting. On the front of active jaw plates are installed. At its

peak, the eccentric shaft and bearings hanging over the frame. Your floor is

supported on the moving parts and. In rolling contact with the moving parts At

the two ends of the eccentric shaft is the flywheel and the pulley is installed

at the groove. The machine body is connected to the machine base and the

slideway of the motor is fixed onto the machine base with bolts.

The supporting

system of moving jaw is equipped with riveting pin connection device. If hard

objects that can not be broken (eg pieces of iron) in the materials crushed, ie

the crusher is overloaded, the pin will quickly rivering break, play a

protective role to preserve other important parts of the crusher from damage.

A grip having a

function of angular displacement provided, installed on the left side of the

machine. This handle is used to adjust the size of the outlet opening. The

distance between the outlet openings can be adjusted by the adjustment of the

handle. In addition, when the jaw plate is abraded, the gap between discharge

openings can be compensated through the adjustment of the handle.

Model

|

Capacity

|

Inlet size

|

Feed size

|

output size

|

Rotating speed

|

power

|

Weight

|

|

kg/h

|

mm

|

mm

|

mm

|

r/min

|

kw

|

kg

|

XPC60×100

|

≤400

|

60×100

|

≤50

|

1-3

|

650

|

1.5

|

110

|

XPC100×150

|

≤1800

|

150×100

|

90

|

5-25

|

380

|

2.2

|

190

|

XPC100×125

|

≤600

|

125×100

|

80

|

1-6

|

380

|

3

|

360

|

XPC150×125

|

≤200

|

150×125

|

100

|

6-38

|

375

|

3

|

417

|

XPC150×200

|

≤2000

|

200×150

|

≤120

|

5-30

|

375

|

5.5

|

450

|

XPC150×250

|

≤3000

|

150×250

|

≤125

|

10-40

|

3750

|

5.5

|

500

|

Model

|

Capacity

|

Inlet size

|

Feed size

|

output size

|

Rotating speed

|

power

|

Weight

|

|

Kg/H

|

mm

|

mm

|

mm

|

RPM

|

KW

|

SP60×100

|

≤720

|

100×60

|

48

|

0.8-15

|

300

|

2.2

|

330

|

SP100×100

|

≤800

|

100×100

|

80

|

0.8-15

|

350

|

3

|

400

|

PEX100×100

|

≤960

|

100×100

|

80

|

< 1mm

Accounts for 96%

|

600

|

2.2

|

300

|

PEX100×125

|

45-600

|

100×125

|

≤80

|

1-15

|

600

|

3

|

450

|

PEX125×125

|

≤1600

|

125×125

|

110

|

1-15

|

600

|

3

|

3000

|

MPE100×150 sealed

|

45-600

|

100×150

|

80

|

1-15

|

420

|

3

|

450

|

MPE100×250 sealed

|

300-100

|

100×250

|

80

|

1-8

|

420

|

4

|

700

|