New XFD Single Flotation Cell Ⅱ is an updated product of XFD Model Single

flotation cell with frequency converter technology, variable speed control of

the wheel, digital display with precise adjustment and reliable operation.

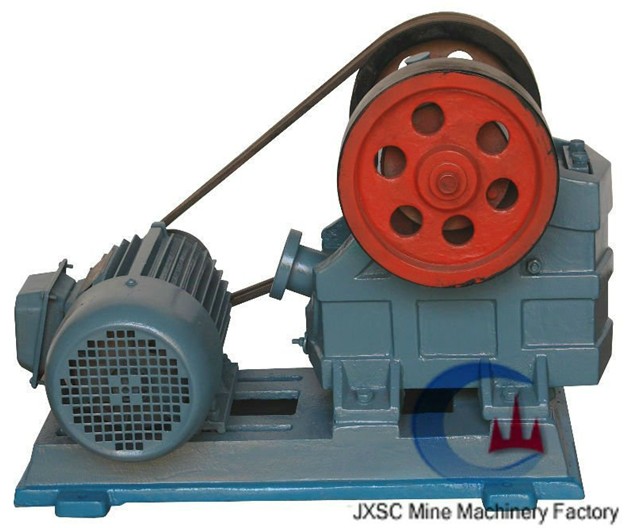

XFD II single-

trough flotation machine is mainly of the following parts:

Body, main shaft

assembly, scraper assembly, trough, and glass knife

Control parts

XFD II single- trough flotation machine:

Control part of

the main shaft frequency conversion stepless speed regulation, control section

scraper speed, etc

The labor force

and voltage XFD II single- trough flotation machine is 220V AC. For the safety

of the people, the machine must be reliably grounded through a grounding

resistance ≤ 4Ω.

New flotation

Laboratory XFD

III single- trough flotation machine is used by mines of geology, Gold

Mining Equipment, building materials, chemicals, etc and

laboratories of scientific institutes, to agitate for, scrub, separate and

select a small amount of ore samples.

New model

ventilation Einzelze ll Flotation of XFD III is a product of the updated XFD

Model Single flotation cell, the adoption of external ventilation device,

adjustable ventilation, frequency conversion technology, variable speed control

of impoeller digital display with precise adjustment and reliable operation (

When the temperature of the temperature control unit ≤ 100 ℃, it can be made to customer's need ).

Such flotation

of the frame part, main shaft driving part, cam, scrapers part, flotation cell,

outside air inflation device, electric control system composed etc.

The air supplied

from the air pump into the air cell, uniformly mixed with the slurry during the

movement of the rotor through the stator and cut small bubbles are mineralized

then prepared.

The rotational

speed of the rotor is infinitely variable and which can be adjusted by

frequency converter.

To fix the

flotation cell, it must be firmly pressed with the hand - drive the screws.

The motion trail

of the scrapping mechanism is circular.