The ZJ series

dregs thick liquid pumps is the our company according to the market demand, the

absorption domestically, outside the advanced technology develops the design of

series product. Pump uses the outstanding water power model design, high

efficiency, the performance is good. The double pump housing structure is the

rate service conveniently. This product engineering factor corresponds "

to pump centrifugal type Dregs thick liquid to " JB/T8096-1998 the

standard.

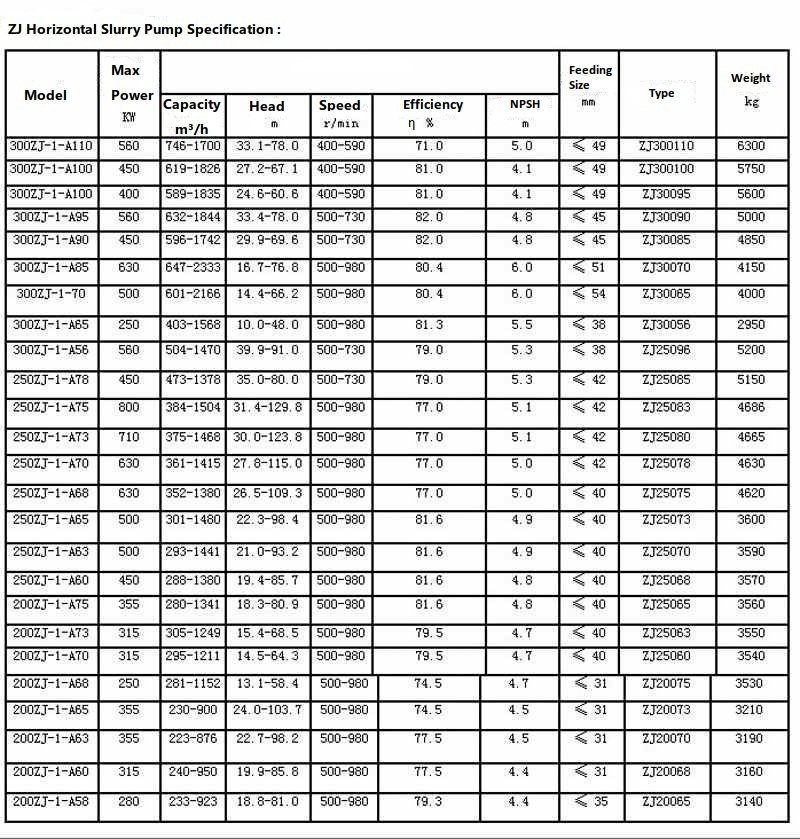

Speed :

electrical machinery straight association transmission 2900/1480/980/730/590 /

r / min

Between the

pulley of the union transfer corresponds to the customer

Can reach

General < = 80 ℃ 110 ℃ Special: Medium

Temperature

Solid fluid

mixture weight concentration: Mortar density < = 45 % Pulp density < =

60%

Current Capacity

Fan Zhuan: 30 - 2000m3 / h

Removes the

range: 15 - 30m

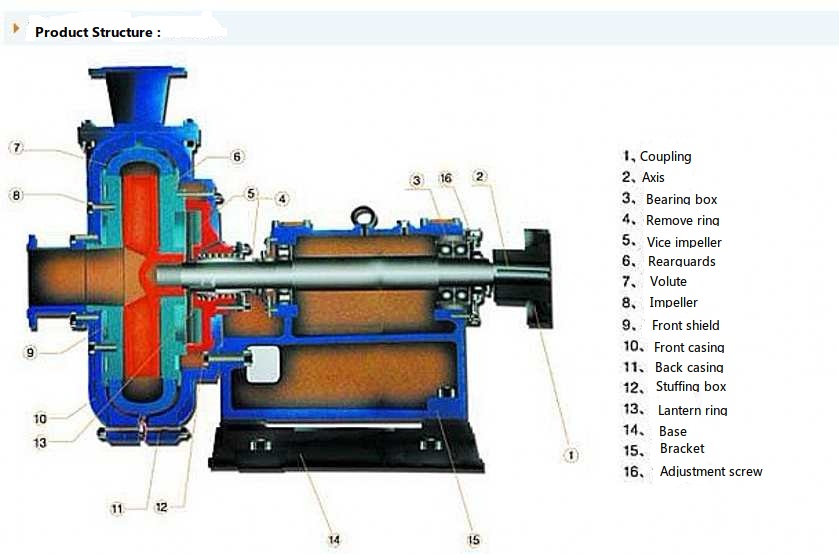

Horizontal Type

The flexible

coupling straight association transmission ( requests under 160kW be possible

to customer pulley variable transmission to use )

Having to pump

Export is possible according to his to turn 4Directions after 90 ℃ gaps ( usually deliver goods exported

vertically upward to be )

As required,

connect it to the pump using

Product

Description:

Under the SP

fluid the dregs thick liquid pumps for vertical centrifugal pumps dregs thick

liquid, immersed below the liquid used in transport, the wholesomeness, the

thick tablet, the highly concentrated dregs thick liquid. Does each axis must

with the seals of the Wasserachseabdichten, is not sufficient in the absorption

amount under the operating mode Can also normal work. SP pump, the float part

are made of the wear-resistant metal. SPR pumps submerged below the liquid

spare parts, bring the Gummiaußenverkleidungzu, is suitable for the transport

of non- edges and corners of wholesomeness dregs thick liquid. After the dregs

thick liquid pond filling level the different length of the pump drive shaft or

intake pipe can be selected. Uses many kinds of speeds and the many types of

aberrations induced manner, under the best operating mode moves, pump service

life long, the movement benefit is high, many kinds of bad transport can

fulfill condition.

Especially

suitable for the transport of aggression, the large pellets, the highly

concentrated dregs thick liquid. Widely applies for department and so on

metallurgy, mine, coal - electricity, building materials, environmental

protection.

SP pumps is the

vertical centrifugal pumps dregs thick liquid pumps theater entrance is

vertical vertical under which export to another page, the pump will turn up.

Upside pump mainly filters the outline, the pump casing, the impeller, the axis

of less than, the protection board, components, and so forth support consists,

pumps, the bearing supporting the pump installed in the liquid, do not to seal

each axis, the part, flowed to the Anti-friction material.

This sand

pumping the transmission pattern is BD and the DC two types, namely leather

belt transmission and straight connecting transmission. Immersed below the

depth of the liquid is possible, to the extent standardize according to the

actual needs of the user to decide.